Content

All issues / Volume 19 (2025) / Issue 1 (January)

This is an editorial article. It has no abstract.

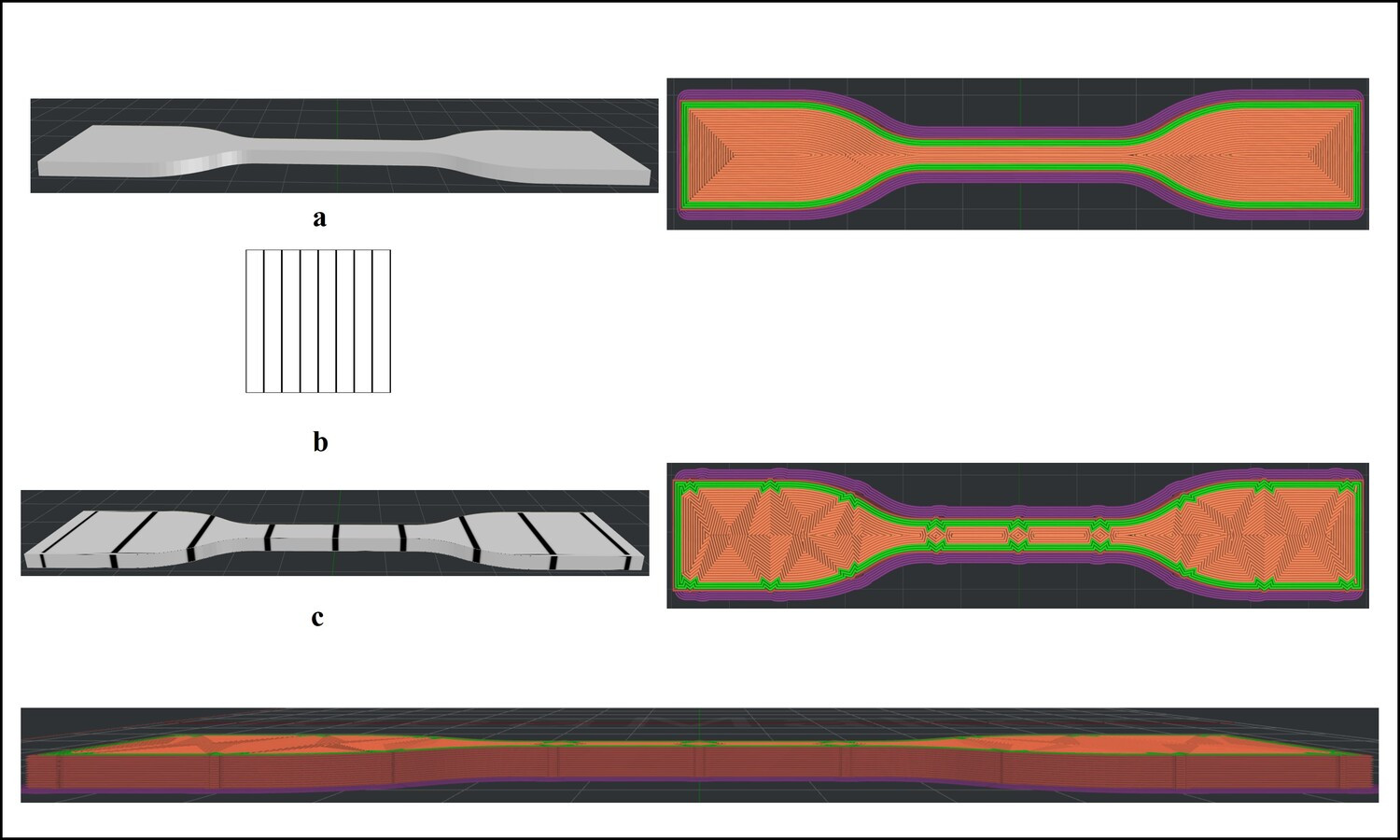

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

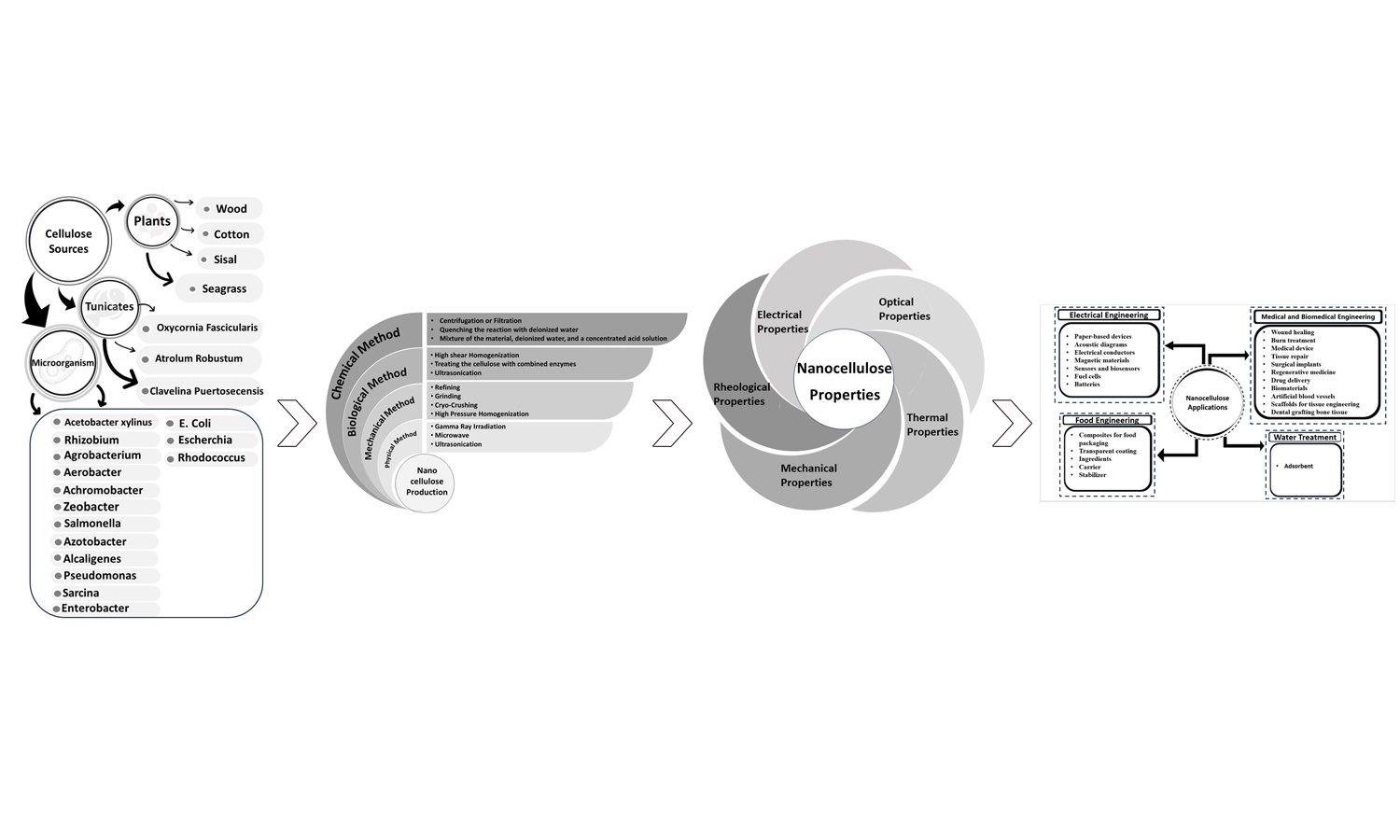

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.

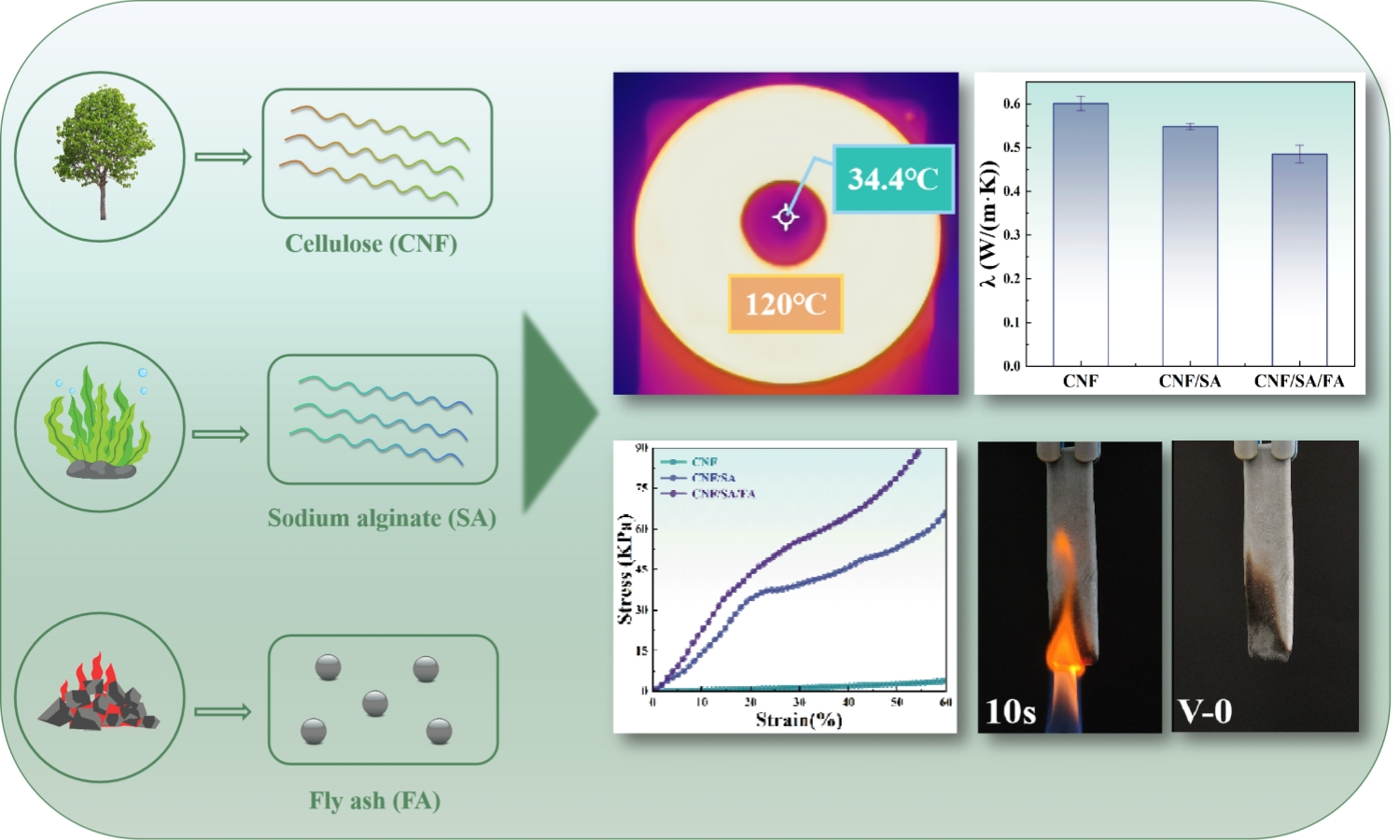

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

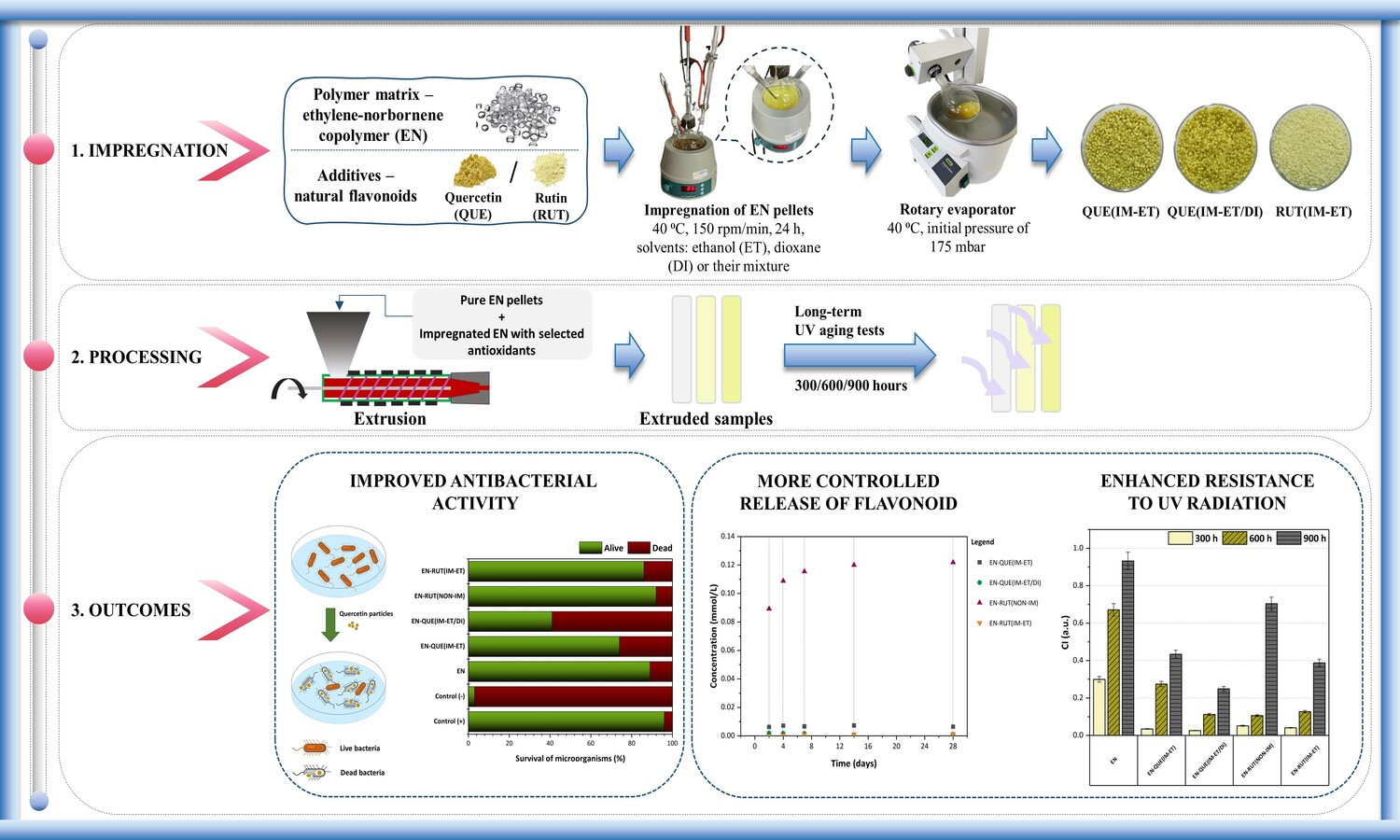

Herein, a novel approach was developed for the introduction of stabilizing compounds into polymers through a pre-impregnation process prior to processing, which is expected to improve their dispersion and, consequently, increase their efficacy. Ethylene-norbornene copolymer (EN) pellets were impregnated with quercetin or rutin in ethanol or a mixture of solvents (ethanol-dioxane (3:1)) for 24 h. Then, EN-based samples containing impregnated pellets were manufactured using a laboratory extruder. The research demonstrated that the materials containing impregnated pellets exhibited improved thermo-oxidation resistance, higher antibacterial effect (the number of dead cells increased from 8 to 59%), and satisfactory photostability. This may be a direct result of their better dispersion degree and their more gradual, controlled release from the EN during operation. If we compare the stabilizing effect of both polyphenols, quercetin was more efficient, which may be attributed to the presence of hydroxyl group at the C3 position in the C ring, which could increase the reactivity of the catechol structure of the B ring. The proposed approach effectively solves the issues that arise during the commonly used processing techniques and may facilitate the broader utilization of natural stabilizers in the polymer industry.

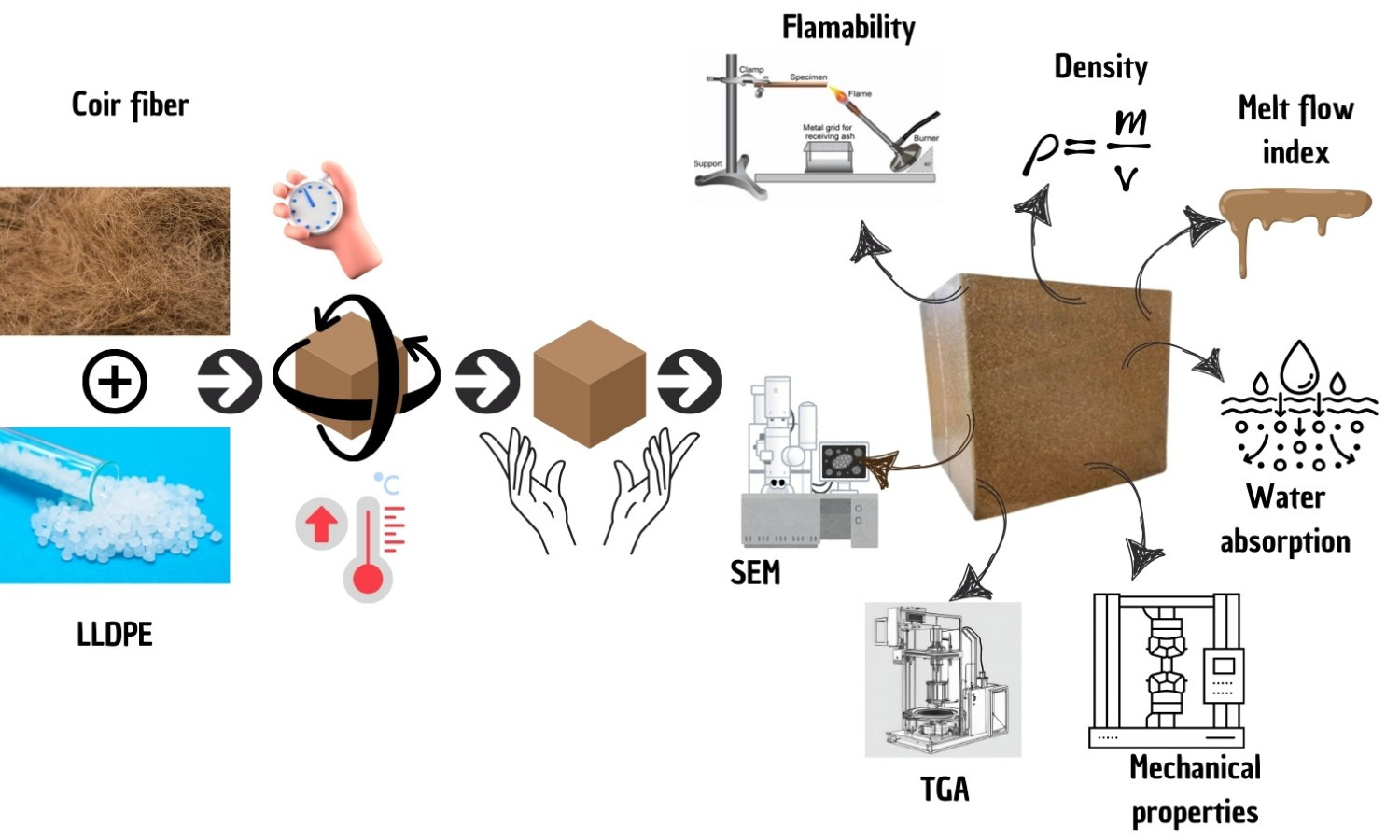

Rotational molding of LLDPE/coir fiber composites: Effect of fiber on mechanical, thermal, morphological and flammability properties

Lumirca Del Valle Espinoza León, Viviane Alves Escócio, Leila Lea Yuan Visconte, Ana Maria Furtado de Sousa, Ana Lúcia Nazareth da Silva, Elen Beatriz Acordi Vasques Pacheco

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

This study uses a rotomolding procedure to produce hollow cubes made of linear low-density polyethylene (LLDPE) and coconut fibers (CF). The purpose is to investigate the effect of different CF content (0, 5, 12.5, and 20 wt%) and size (100 and 50 mesh) on composite properties. As the CF content rises, the density of all composites decreases due to an increase in material porosity, a result of poor adhesion between the fiber and LLDPE. Impact strength reduced as the content of CF increased, except for the composite with 5 wt% of CF and 50 mesh size. The ineffective adhesion between coir fibers and LLDPE, along with the presence of voids in the matrix, caused the mechanical properties to deteriorate as the CF content increased. The flammability test revealed that all samples dripped. The neat LLDPE sample deformed, whereas the LLDPE/CF composites maintained their shape. This behavior suggests that CF plays a structural role in burning composites. Maleic anhydride-grafted polyethylene (MAPE), calcium stearate, and magnesium stearate additives did not contribute to reducing the composite’s porosity. MAPE was the only additive that did not reduce the elastic modulus of composites.

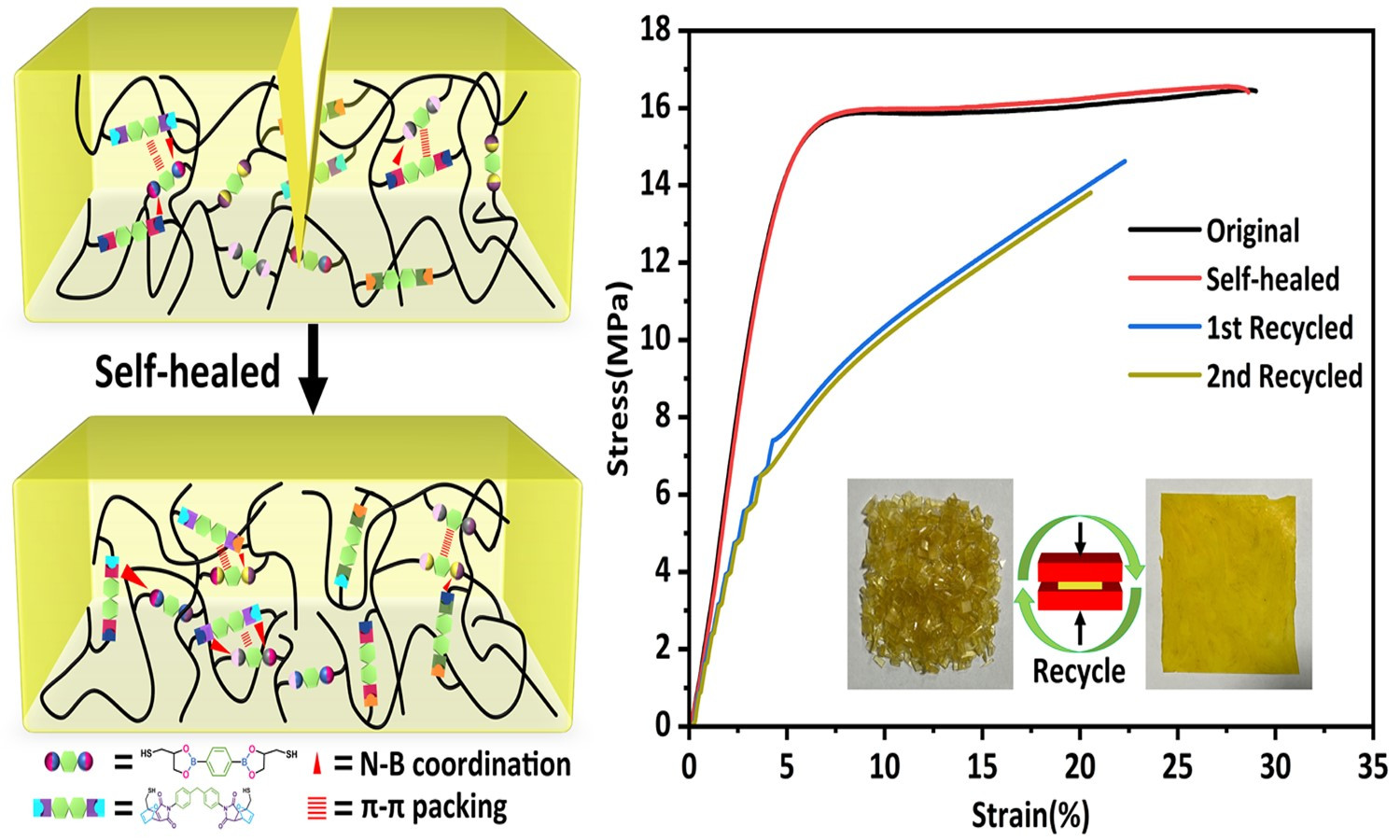

Recyclable high-strength polybutadiene-based rubber with self-healing and shape memory properties via dynamic boronic ester and Diels-Alder chemistry

Shengao Yang, Yan Wang, Fang Wang, Kaiyi Zhang, Xinxin Lv, Hao Teng, Rui Zheng, Faliang Luo, Qian Xing

Vol. 19., No.1., Pages 94-106, 2025

DOI: 10.3144/expresspolymlett.2025.7

Vol. 19., No.1., Pages 94-106, 2025

DOI: 10.3144/expresspolymlett.2025.7

Dynamic cross-linked networks (DCNs) endow thermoset rubber with self-healability and recyclability to extend its lifetime and alleviate environmental pollution. However, the contradiction between high self-healing and mechanical properties in DCNs rubber is always difficult to be resolved. Herein, we used boronic ester (BO) and Diels-Alder dynamic covalent bonds (DA) to synthesize polybutadiene-based dual networks rubber (PB-BO-DA) via thiol-ene reaction. This approach achieved a tensile strength of 16.46 MPa and 99% self-healing efficiency, facilitated by extensive intermolecular interactions (π-π packing and N-B coordination) and fully dynamic cross-linking. In addition, multiple dynamic cross-linked networks (MDCNs) polybutadiene-based rubber also show excellent shape memory ability and recyclability. This strategy might open a helpful pathway to fabricate intelligent multifunctional polymers with high strength and high self-healing efficiency.

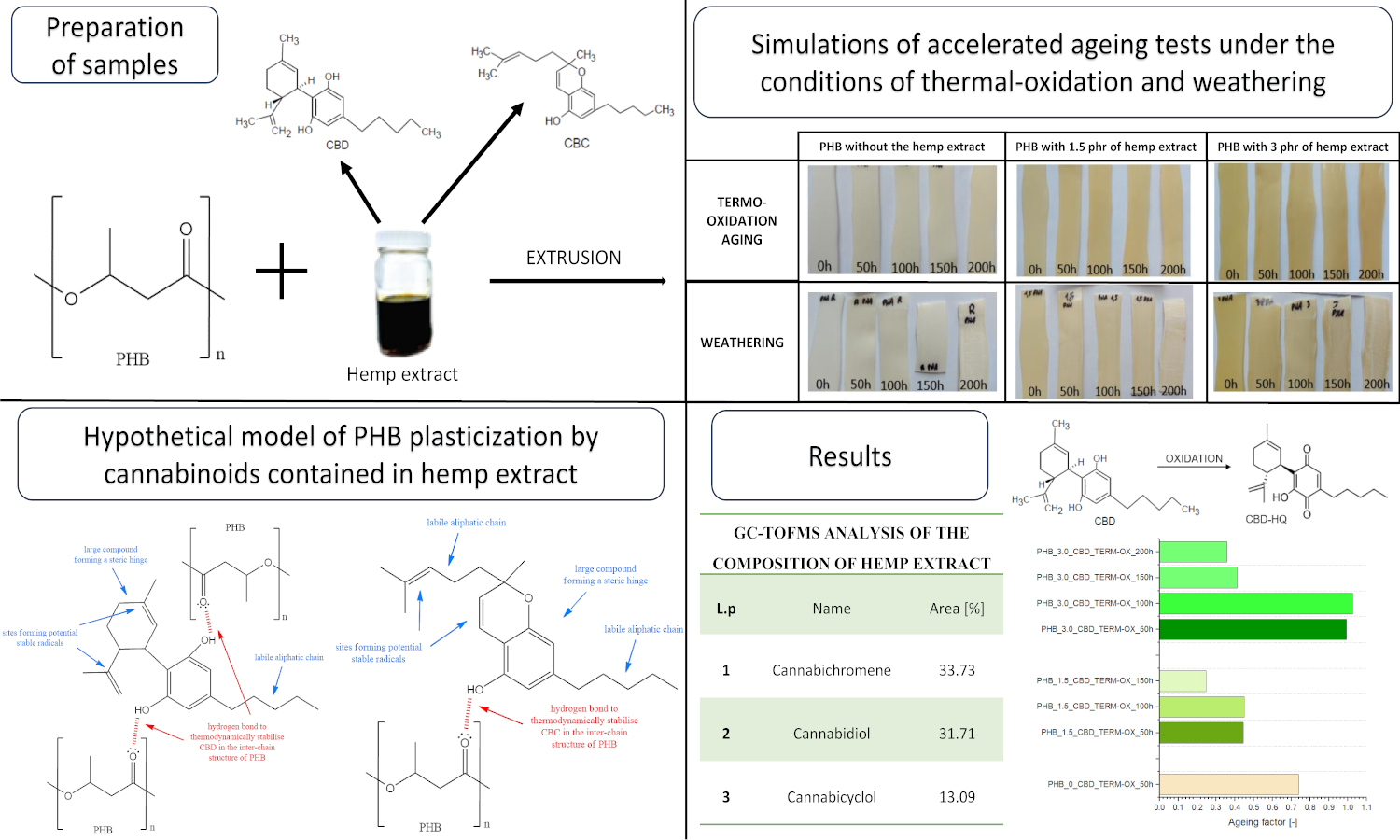

Biodegradable biopolymers like polyhydroxybutyrate (PHB) hold promise for sustainable packaging, but their inherent degradability reduces material stability. Synthetic stabilizers, though effective, raise environmental and potential toxicity concerns. This study explores a multifunctional natural anti-aging agent: a hemp extract rich in cannabidiol (CBD) and cannabichromene (CBC). PHB composites with varying hemp extract concentrations were prepared and subjected to thermooxidative and weathering aging. Characterization employed FTIR-ATR, carbonyl index, and spectrophotometry. Static mechanical properties, DSC, and surface free energy (SFE) were also assessed. Notably, the hemp extract exhibited stability under ambient conditions but showed migration with time and aging. The results suggest a plasticizing effect on PHB and highlight the contrasting roles of the extract: inhibiting thermooxidative aging while potentially accelerating aging under atmospheric conditions. This opens avenues for tailoring material durability, further evaluated by life cycle analysis (LCA). This work represents one of the first investigations into hemp extract as an anti-aging agent for eco-friendly polymers, expanding the knowledge base of natural multifunctional additives.