Content

All issues / Volume 18 (2024) / Issue 12 (December)

This is an editorial article. It has no abstract.

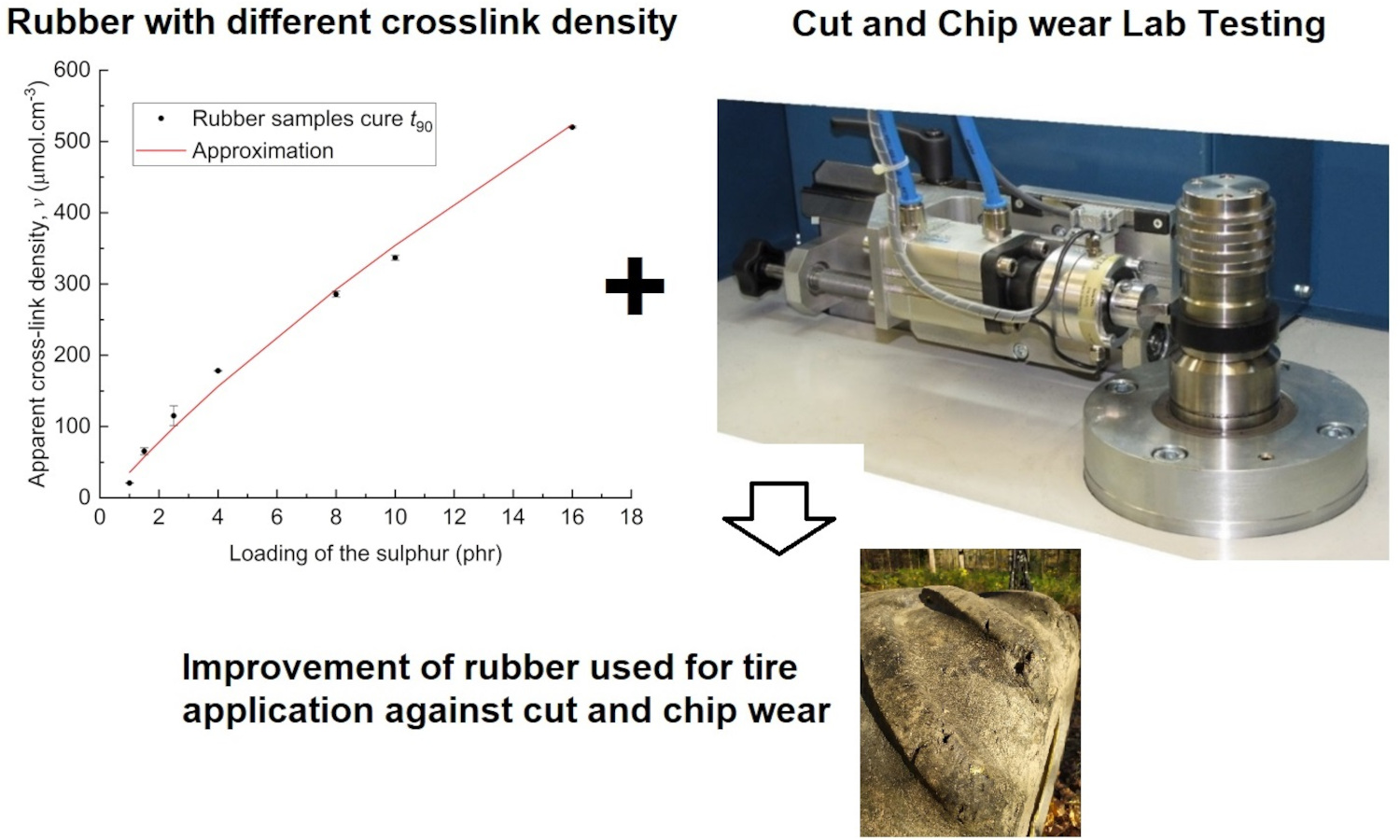

This paper extends previous studies by the authors that aimed to describe the effect of apparent cross-link density (CLD) of the rubber polymer networks on the fracture mechanism caused by cut and chip (CC) wear of natural rubber (NR), demonstrating the positive effect of conventional vulcanization (CV). This work is focused on the determination of the effect of CLD while keeping constant the accelerator-to-sulfur ratio A/S = 0.2, typical for CV systems. For this ratio, different sulfur quantities were chosen, and the concentration of the accelerator N-tert-butyl-benzothiazole sulphonamide (TBBS) was calculated to achieve CLDs in a range from 35 to 524 μmol・cm–3. Standard analyses such as tensile tests, hardness, rebound resilience and DIN abrasion were performed. From these analyses, the optimum physical properties of the NR-based rubber were estimated to be in the CLD range of approximately 60 to 160 μmol・cm–3. A CC wear analysis was performed with an Instrumented cut and chip analyzer (ICCA) and it was found that the highest CC wear resistance of the NR is in the CLD range of 35 to 100 μmol・cm–3. Furthermore, the effect of straininduced crystallization (SIC) of NR on CC wear and its dependence on the CLD region was discussed. For the first time, we determine a CLD range for a CV system in which the material achieves both optimal mechanical properties and CC wear resistance.

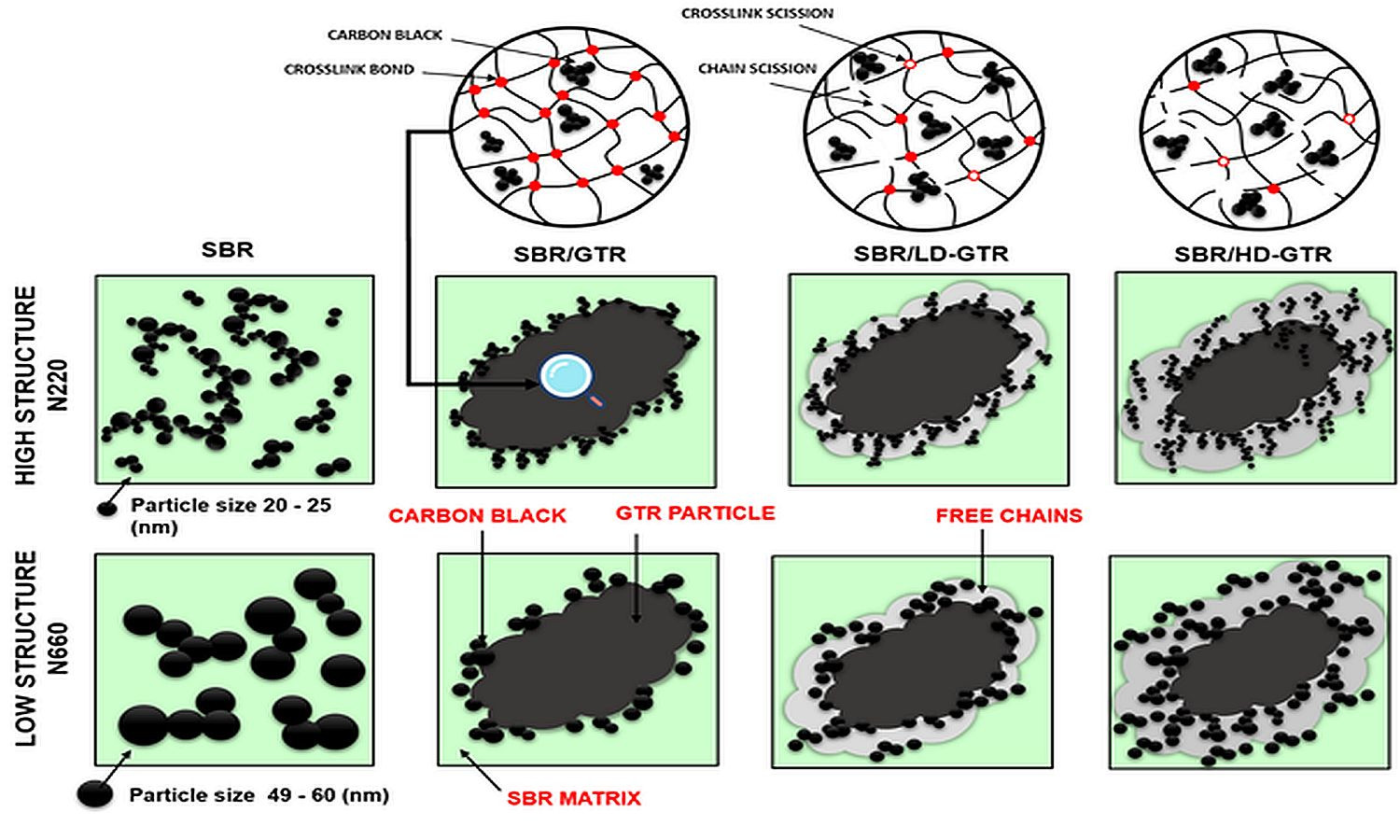

Carbon black migration between ground tire rubber (GTR) and rubber matrix is essential in developing high-performance rubber/GTR composites. In this work, carbon black N220 (surface area: 107.1 m2/g, particle size: 20–25 nm) and N660 (surface area: 33.1 m2/g, particle size: 49–60 nm) were used as the reinforcement fillers for styrene-butadiene rubber (SBR) blended with reclaimed GTR. The combined effects of GTR devulcanization level and carbon black grade on the properties of SBR/GTR composites were investigated considering curing characteristics, thermal stability, physico-mechanical properties, dynamic mechanical properties, swelling behavior, and morphology. The results showed that, regardless of GTR devulcanization level and carbon black grade, application of GTR resulted in deterioration of mechanical properties compared to a reference sample without GTR. It was observed the reinforcement effect of carbon black in SBR/GTR composites was more visible with higher devulcanization level of GTR and lower particle sizes of carbon black fillers. SBR/GTR composites reinforced with carbon black N220 were characterized by tensile strength in the range of 15.3–16.3 MPa and abrasion resistance in the range of 120–123 mm3, which justify their potential application in the manufacturing of technical rubber goods or footwear.

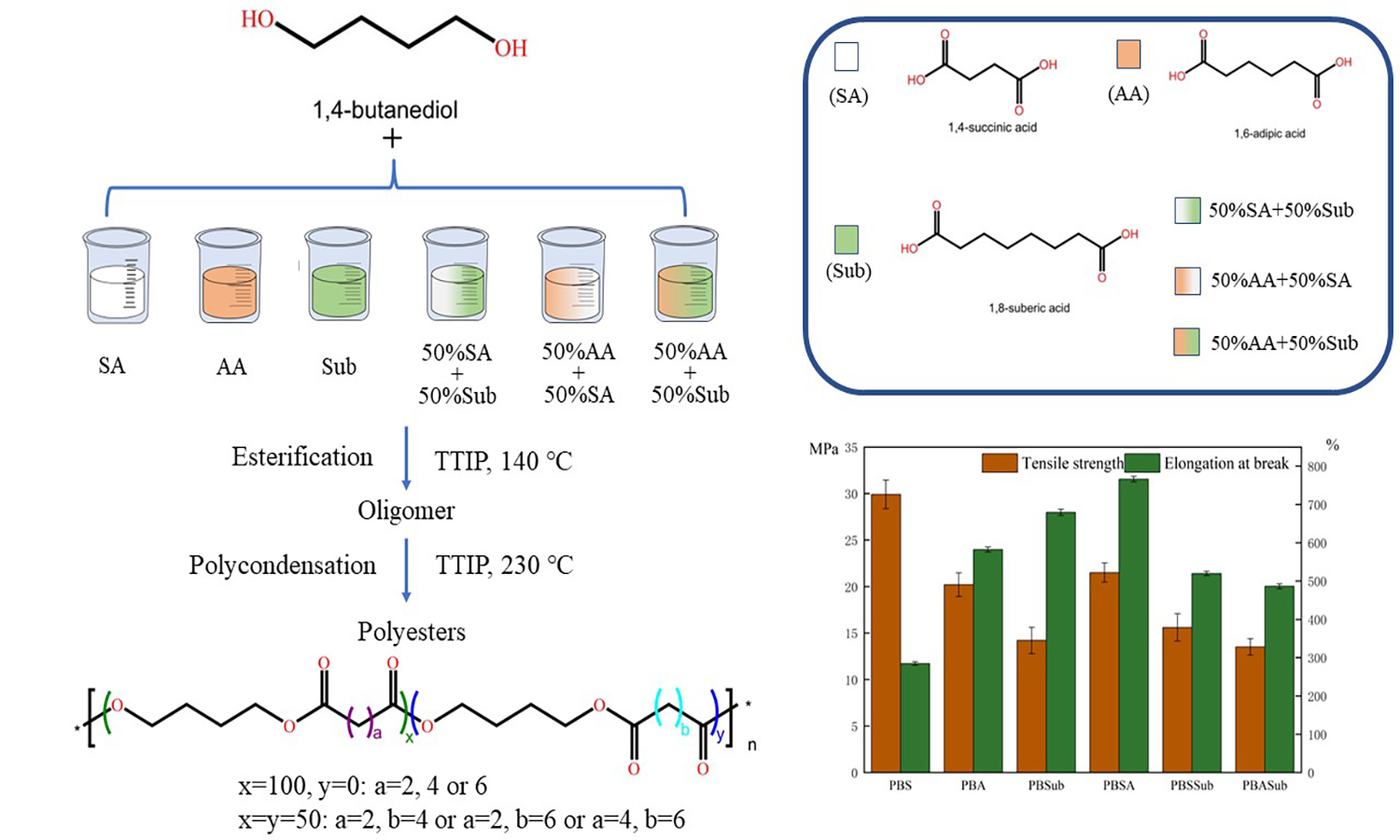

Polybutylene succinate, polybutylene adipate, polybutylene suberate and their copolyesters were synthesized. The physical properties and biodegradability of these polyesters were controlled by adjusting the composition of carboxyl monomers. Compared with the homopolyesters, the addition of comonomer during polymerization resulted in the formation of copolyesters with lower melting temperatures and crystallinity. Among them, poly(butylene succinate-co-adipate) (PBSA) had the lowest crystallinity, and poly(butylene adipate-co-suberate) (PBASub) had the lowest melting point. The elongation at break and tensile strength of PBSA was 766.2% and 21.5 MPa, respectively. Enzymatic degradation by Fusarium solani cutinase (FsC) showed that both the crystalline and amorphous regions of the polyester were simultaneously degraded by FsC, and the crystal structure of the polyester was not disrupted. FsC preferentially got attached to the surface of polyesters, subsequently attacked the center of the films, and the water penetrated the amorphous region, leading to enhanced enzymatic hydrolysis. The biodegradability of copolyester was higher than that of homopolyesters. PBSA and poly(butylene succinate-co-suberate) (PBSSub) were completely degraded in about 10 h, and can be used in agricultural, automotive, electronics, biomedical materials, packaging, etc.

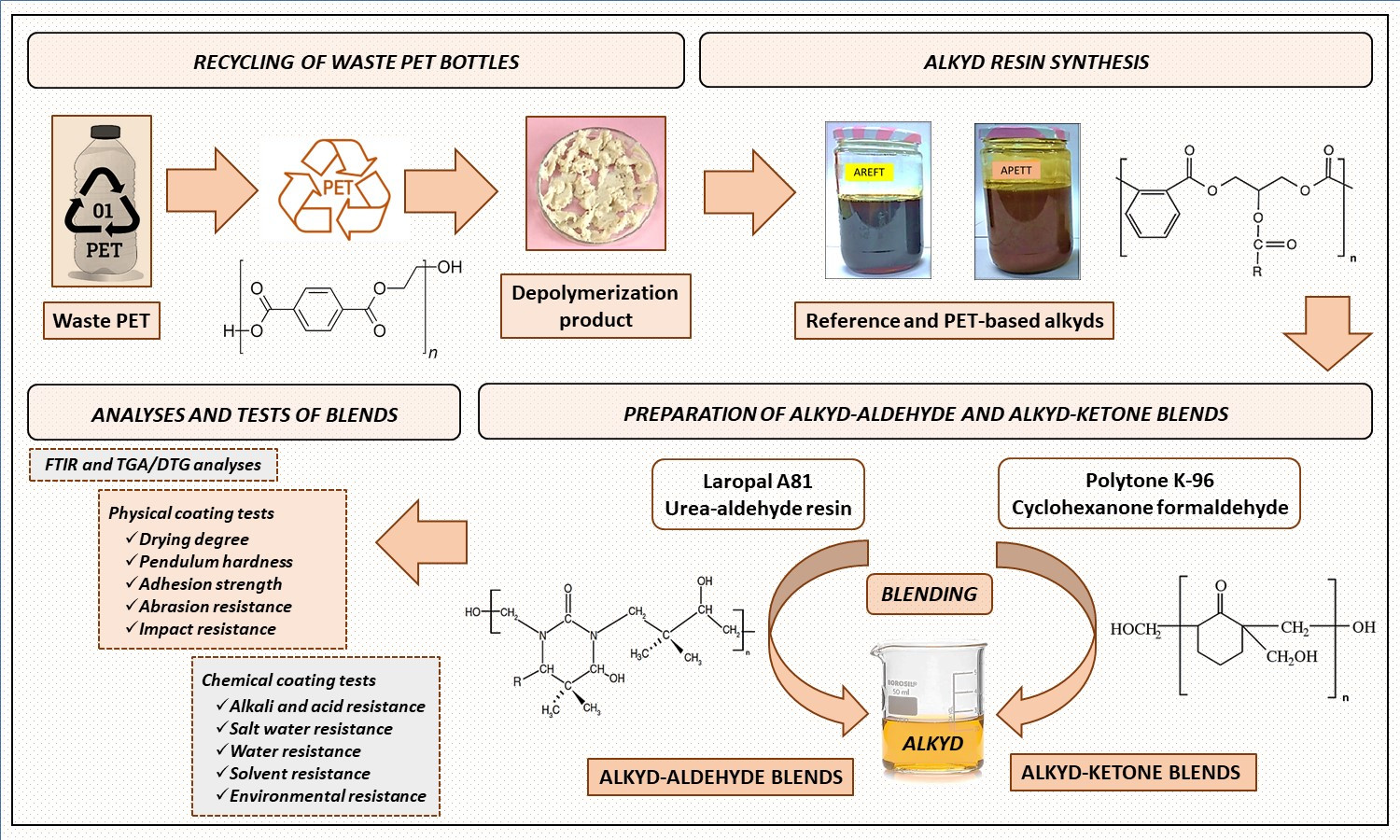

This study aims to develop alkyd-aldehyde and alkyd-ketone blends by modification of waste poly(ethylene terephthalate) (PET) based alkyd resin with urea-aldehyde (UA) and cyclohexanone formaldehyde (CHF) resins for use in coating applications. PET flakes were depolymerized by simultaneous hydrolysis-glycolysis reaction, and depolymerization product (DP) was used completely instead of the diol in the alkyd synthesis. For comparison, reference alkyds without PET were also synthesized. The effect of modifier resin at different ratios and the presence of DP on the coating and thermal properties of blend films were investigated. Medium-hard/hard and gloss/high gloss films with excellent adhesion and impact resistance were obtained from both blends. These films also demonstrated superior chemical and environmental resistance. Blends with CHF resin had better alkali resistance than those with UA resin. In PET-based blends, thermal resistance significantly increased with the addition of the CHF resin to the alkyd resin. Notably, the use of DP did not show a negative effect on the properties of alkyd resin and blend films. On the contrary, much better results were obtained than the alkyd resin alone. Overall, the modification with UA and CHF modifiers and using DP improved the coating properties of the blends. These blends are expected to be considered a sustainable and environmentally friendly alternative for designing versatile coatings for various applications.

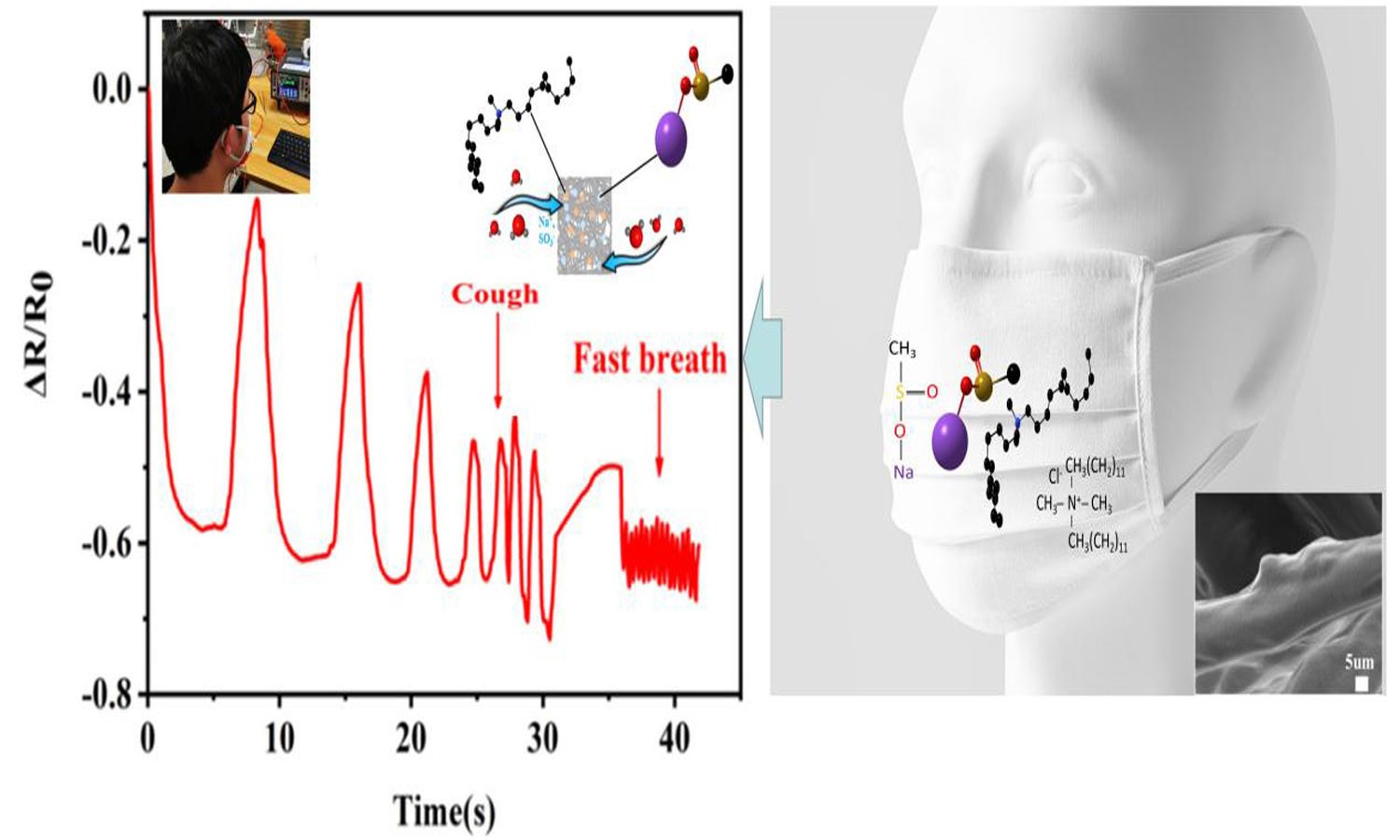

Currently, polylactic acid (PLA) is an attractive alternative to polypropylene (PP) because of its biodegradability. This study introduces a novel modification strategy for PLA by creating a multifunctional ionization layer with ionic salts. This approach achieves humidity sensing, reliable antibacterial properties, and excellent degradability simultaneously. The modified PLA textile sensor exhibits high sensitivity to respiratory humidity (0.92 at 90% RH), with ultrafast response (0.12 s) and recovery times (0.16 s). Additionally, the textile demonstrates excellent antibacterial performance against both E. coli (99.9%) and S. aureus (99.9%) after 1 h of contact. It also shows notable biodegradability with a weight loss rate of 60.38% after 30 days. Also, the ionic salt mechanism is explained through dynamic ionization interactions attributed to the modified ionic salts, which feature both long-chain alkanes and active ions. This work presents a new method to enhance the respiratory detection and antibacterial performance of biodegradable masks.

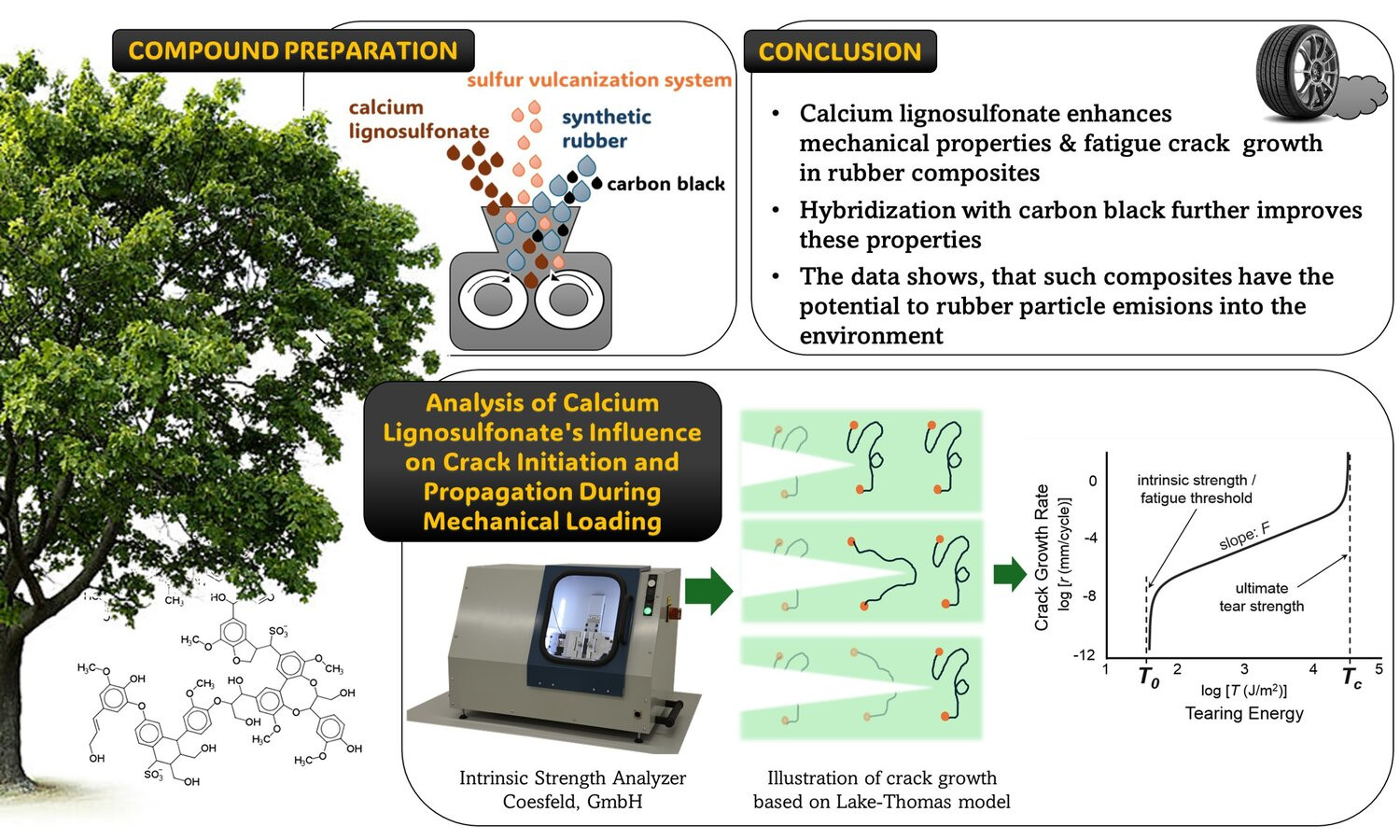

This study explores the transformative potential of calcium lignosulfonate (CaL) as a sustainable additive in rubber composites based on nitrile rubber (NBR) and styrene-butadiene rubber (SBR). Through comprehensive mechanical testing, fatigue crack growth (FCG) analysis, and scanning electron microscopy (SEM), we evaluated the tensile strength, elongation at break, surface morphology, and crack growth behavior of these innovative composites. By incorporating CaL into carbon black-reinforced rubber compounds (RUB/CB) based on nitrile rubber and styrene-butadiene rubber, we achieved good dispersion of both components as well as satisfactory morphology, resulting in tensile strengths of 16.3 and 12.7 MPa, respectively. While the CB/CaL hybrid did not significantly influence the intrinsic strength of the rubber samples, the ultimate strength of these compounds increased drastically – over five-fold compared to RUB/CB – indicating great potential for real-life applications. This study underscores the promise of lignin-based additives in the development of eco-friendly, highperformance rubber materials.

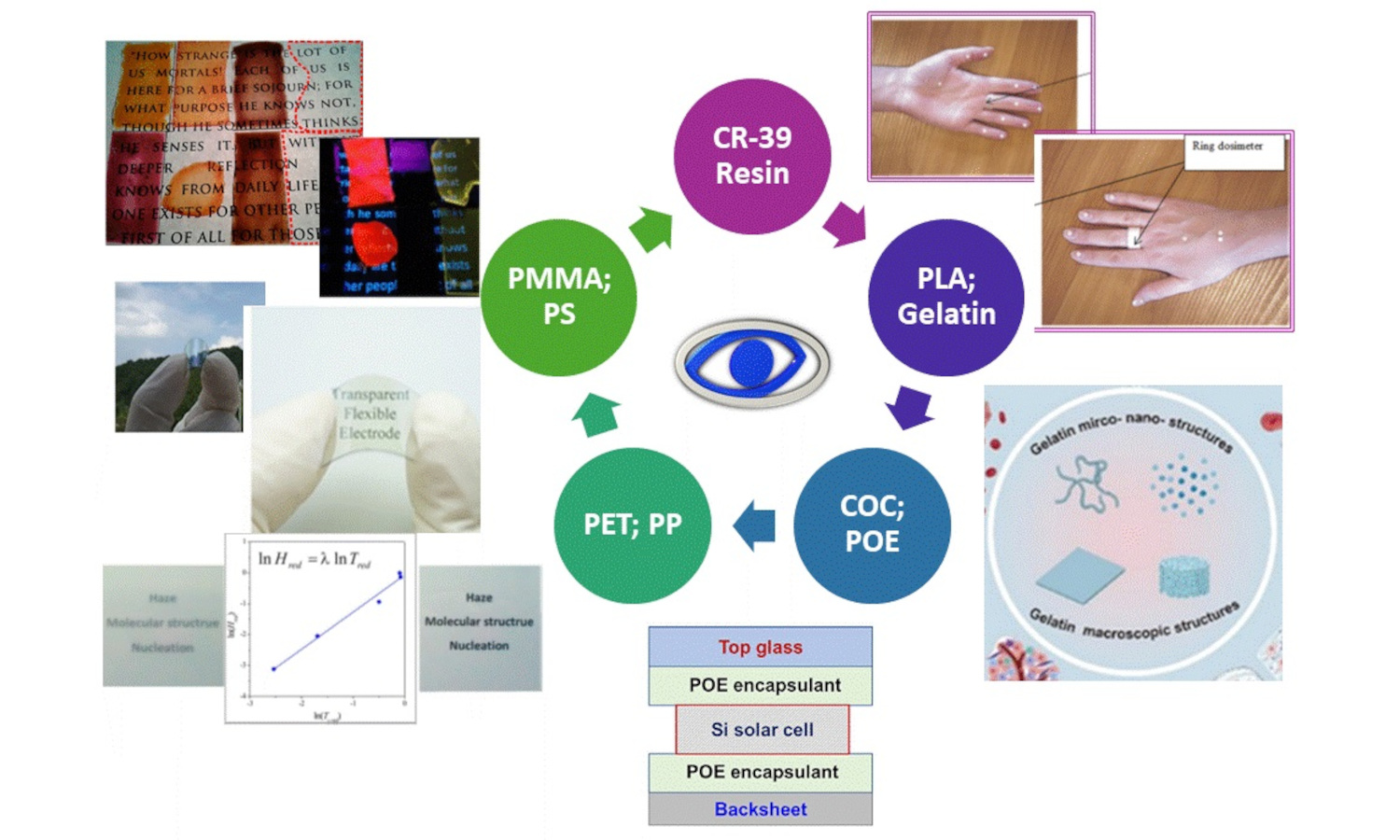

Recently, there has been growing interest in materials that combine the advantages of glass and polymer materials. Such a combination results in a kind of hybrid glass-polymer optics that meets the requirements for high-quality imaging in various environmental conditions. So far, the literature on these materials is quite scarce. This article is an attempt to review the most important reports on the topic of available polymers with optical properties, dividing them into groups, i.e. synthetic optical polymers (including polymethylmethacrylate, polyethylene terephthalate, polypropylene, cyclic olefin copolymers and polyolefin elastomers) and biopolymers (including polylactide and gelatin). A separate place and chapter is given to transparent CR-39 plastic and the issue of individual dosimetry for radon detection. Moreover, testing methods for measuring the most important optical properties of polymers and their major applications are briefly discussed.