Content

All issues / Volume 18 (2024) / Issue 9 (September)

This is an editorial article. It has no abstract.

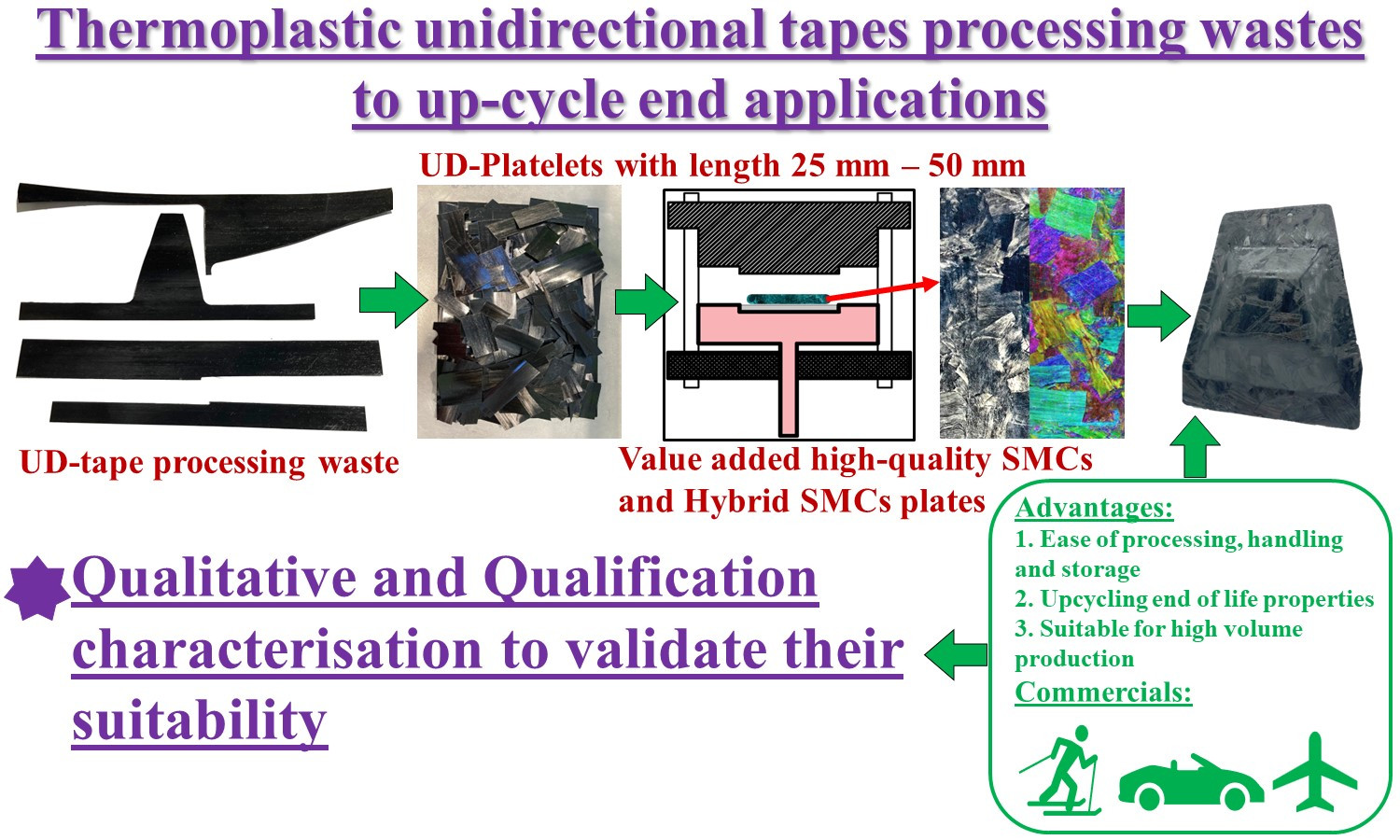

Thermo-mechanical characterisation of polycarbonate-based sheet moulded composites fabricated from off-cut waste unidirectional tapes

Chethan Savandaiah, Andreas Kapshammer, Bernhard Plank, Vanja Stolcer, Christian Marschik, Zoltan Major

Vol. 18., No.9., Pages 883-900, 2024

DOI: 10.3144/expresspolymlett.2024.66

Vol. 18., No.9., Pages 883-900, 2024

DOI: 10.3144/expresspolymlett.2024.66

Thermoplastic (TP) composites, known for their ease of handling, suitability for high production rates, and recyclability, are emerging as a promising alternative to thermoset-based composites. The expected growth in TP-based composites in automotive, sports, and aerospace industries may result in increased post industrial waste. To address this, we repurposed our in-house process scrapped carbon fibre-reinforced polycarbonate tapes into sheet moulding compounds (SMCs) and Hybridised SMCs (Hy-SMCs) using compression moulding. In Hy-SMCs, the top and bottom layers were unidirectional tapes, while the core section had randomly oriented platelets in a 50:50 ratio. Our evaluation included qualitative and thermo-mechanical standard tests. The incorporation of unidirectional tapes in Hy-SMCs significantly improved the tensile and flexural properties of SMCs. Specifically, these enhancements resulted in an impressive 81 to 85% increase in mechanical strength compared to the standard aluminium grade. Additionally, Hy-SMCs exhibited a 120 to 130% increase in tensile and flexural properties compared to SMCs. Fractography revealed a complex relation between fractured surfaces, with multimode failures in both SMCs and Hy-SMCs. Also, the non-destructive evaluation showed platelet reorientation during consolidation and localised voids with increased specimen thickness.

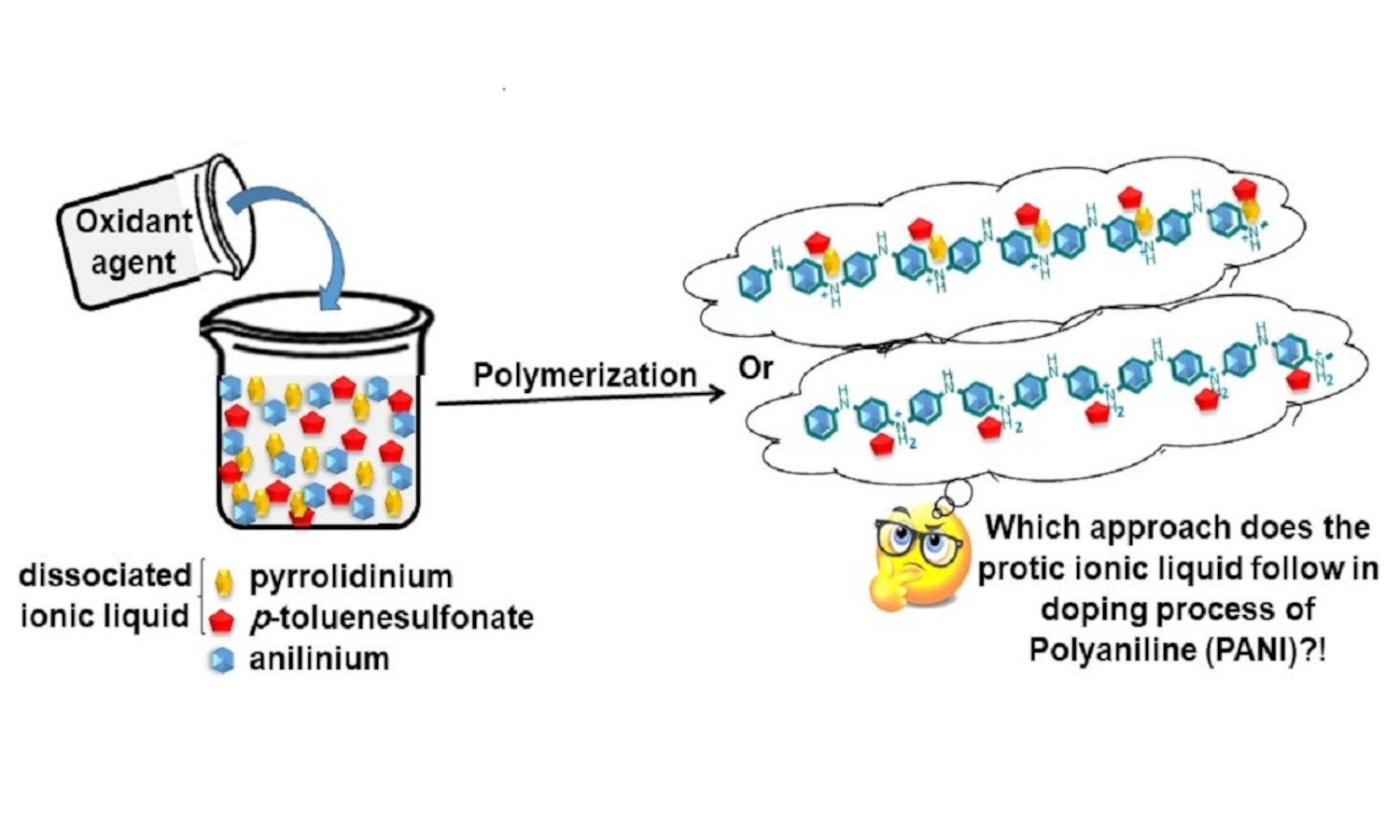

Noncovalent functionalisation of polyaniline with the ionic liquid: An unneeded asset to prepare the emeraldine salt form of polyaniline using protic ionic liquids as polymerisation medium

Fatima Al-Zohbi, Fouad Ghamouss, Bruno Schmaltz, Mohamad Fadel Tabcheh, Mohamed Abarbri, Khalil Cherry, Mustapha Zaghrioui, François Tran-Van

Vol. 18., No.9., Pages 901-910, 2024

DOI: 10.3144/expresspolymlett.2024.67

Vol. 18., No.9., Pages 901-910, 2024

DOI: 10.3144/expresspolymlett.2024.67

Since the properties of polyaniline (PANI) are widely related to the type of its dopant, the present manuscript has an objective to define whether and to what extent the protic ionic liquids contribute to doping PANI. Hence, pyrrolidinium p-toluenesulfonate [Pyrr][PTS] – a protic ionic liquid – has been investigated either as a polymerisation medium or as a secondary dopant. As for the polymerisation medium, it was found that binary mixtures of [Pyrr][PTS]/water, with different weight ratios, are convenient to prepare PANI in emeraldine salt form. Furthermore, the structural analysis of the resulted PANI has revealed that the cation of [Pyrr][PTS] does not functionalise PANI backbone and [Pyrr][PTS] acts like the typical Brřnsted acid in doping PANI, regardless of the amount of [Pyrr][PTS] in the polymerisation medium. To confirm this conclusion, [Pyrr][PTS] has also been studied as a secondary dopant: the conventional PANI has been prepared, deprotonated then dispersed into [Pyrr][PTS]/water with different formulations. The results have shown that [Pyrr][PTS] leads to the formation of reprotonated PANI without altering structural change. One can thus conclude that the noncovalent functionalisation of PANI with the cation of the protic ionic liquids is not an exigent requirement to prepare the emeraldine salt form of PANI in aqueous solutions of protic ionic liquids.

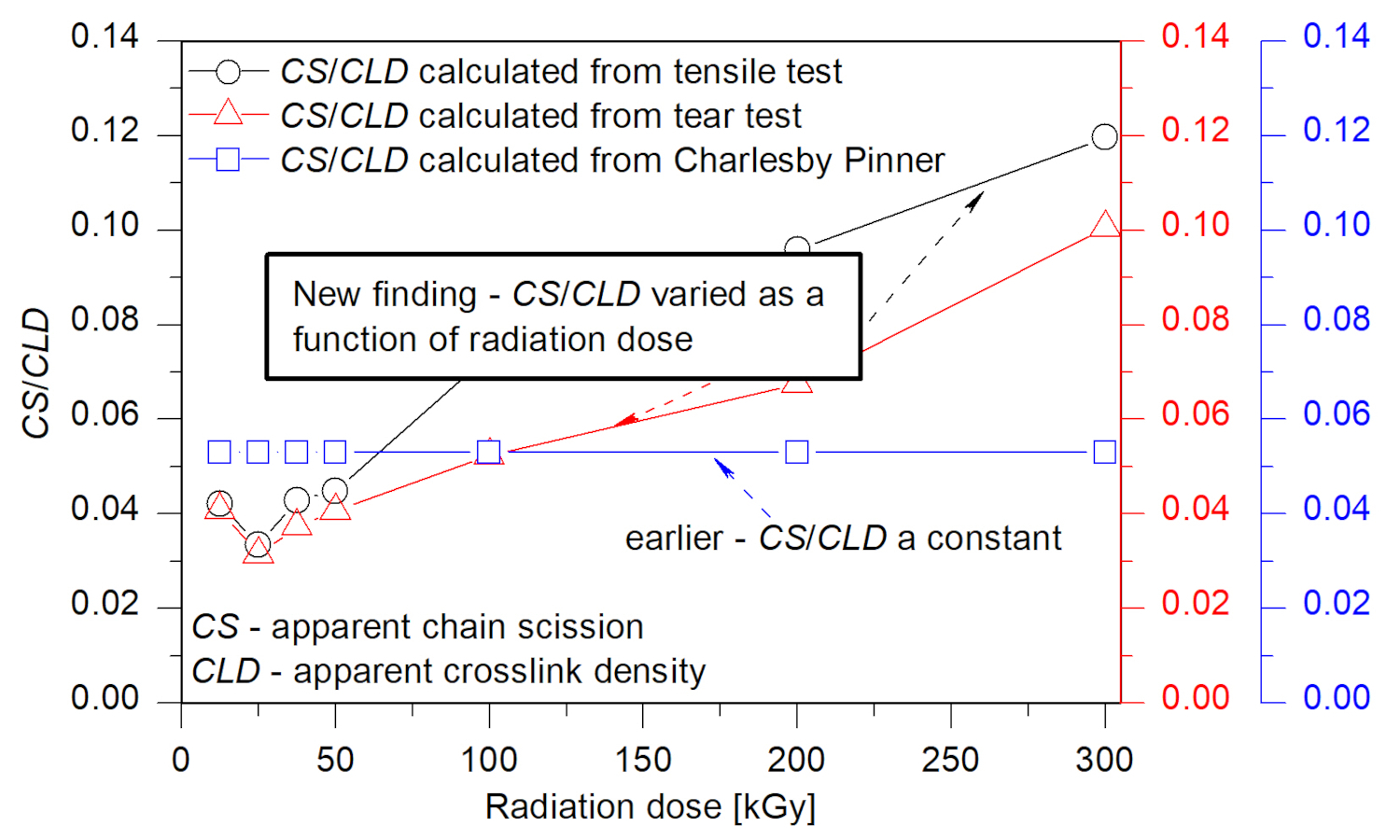

Mathematical function using mechanical properties to calculate chain scission as a function of radiation dose in electron beam treated styrene-butadiene-styrene block copolymer

Sanjoy Datta, Ondřej Peter, Evghenii Harea, Radek Stoček, Kinsuk Naskar

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

Electron beam (EB) treatment of a high vinyl styrene-butadiene-styrene (SBS) block copolymer was accomplished by exposing the polymer to high-energy electrons generated from an electron accelerator. This resulted in the formation of free radicals of carbon on the polybutadiene units in the backbone of the elastomer and subsequent radical coupling to produce cross-links. In the process, some unavoidable chain scission (CS) also occurred. An attempt was made to mathematically trace the nature of the CS as a function of radiation dose with the aid of the experimentally determined cross-link density (CLD), tensile strength and tear strength, the latter three also obtained as functions of radiation dose. The radiation dose was varied from 12.5 to 300.0 kGy in multiples of 12.5 kGy. The novelty of the work was, in part to create a function that can be used to calculate chain-scission in dependence of EB radiation dose. It was found that a change in the ratio of CS to CLD occurred as a function of radiation dose over the previously calculated constant ratio, using the Charlesby-Pinner equation.

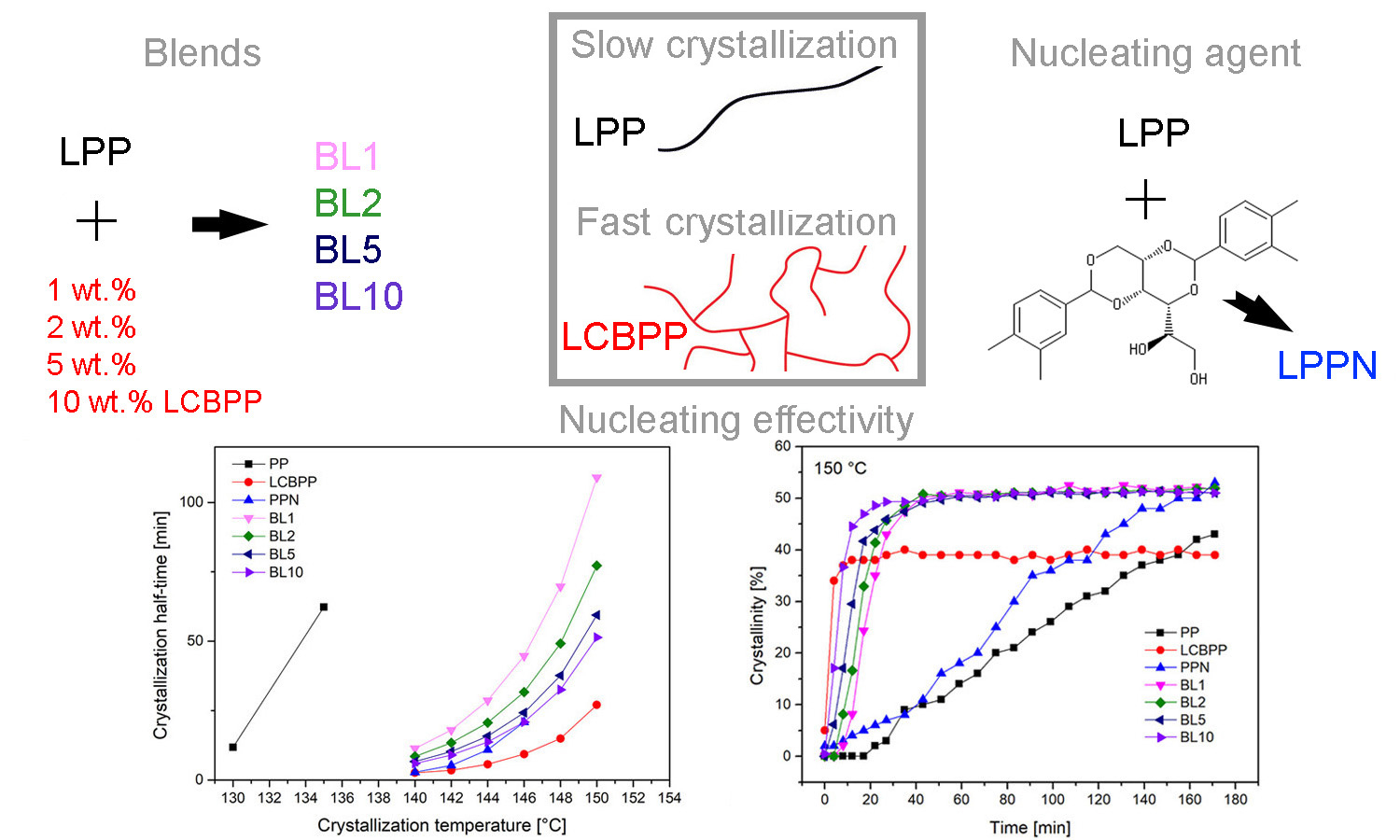

This study compares the efficiency of commercially available sorbitol-based clarifying agent (NA) and varying amounts of long chain-branched polypropylene (LCBPP) acting as a specific α-nucleating agent for linear polypropylene (PP). The sorbitol-based clarifying agent, 1,3;2,4-bis(3,4-dimethyl benzylidene)sorbitol (Millad 3988), in concentration 0.2 wt%, and LCBPP in the concentration of 1, 2, 5 and 10 wt% were mixed into PP. The comparison of the effect of NA and long branches under isothermal conditions on the crystallization process, crystallinity and polymorphic composition was realized by differential scanning calorimetry and wide-angle X-ray scattering. The addition of long chain-branched polypropylene, even at the lowest concentration, performs better at higher crystallization temperatures and has a superior effect on the crystallization process, crystallization rate and overall crystallization than the addition of NA.

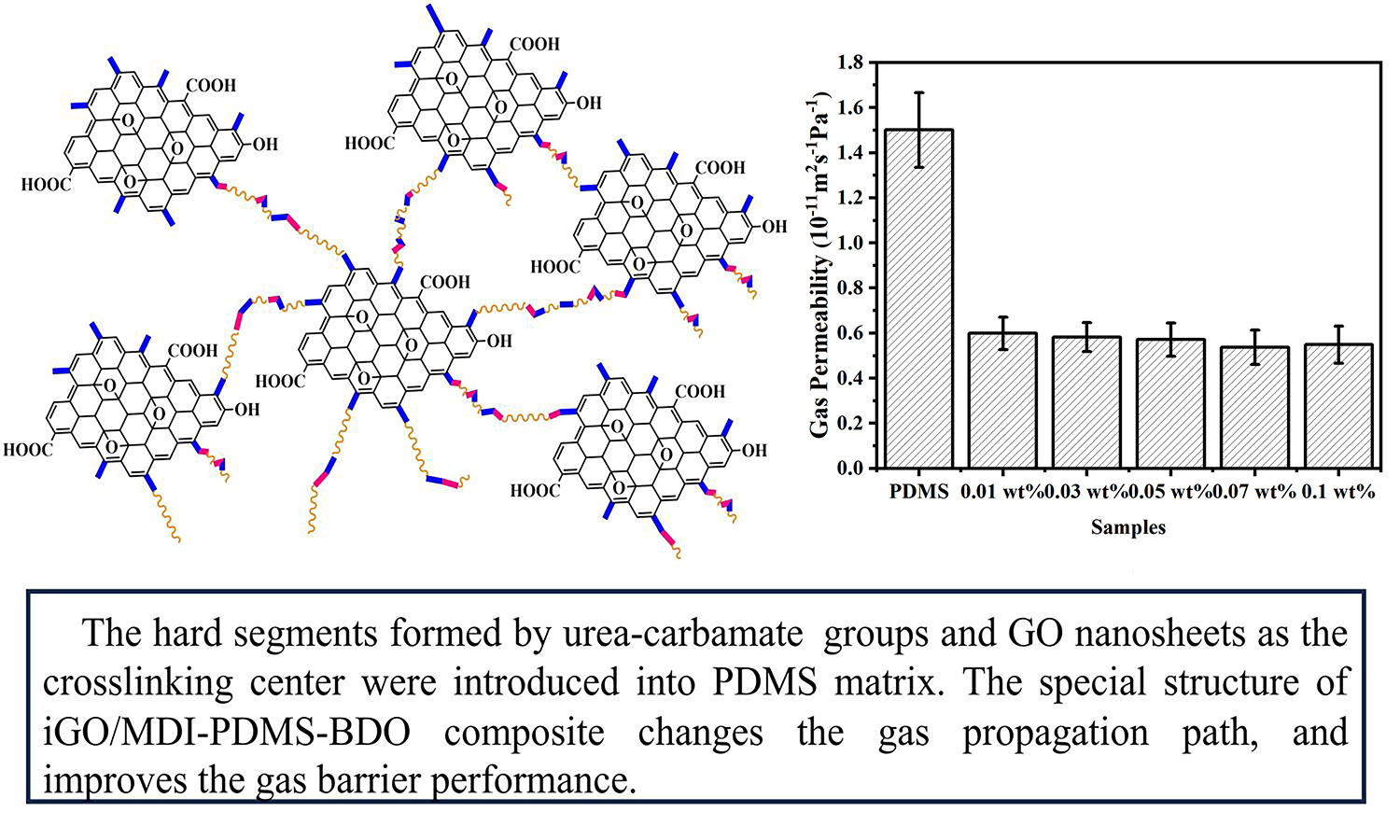

Polydimethylsiloxane has the characteristics of low-temperature flexibility and excellent aging resistance. However, high molecule mobility and weak interactions between PDMS molecules result in poor mechanical strength and deficient gas barrier properties of PDMS composites. Herein, diamino-polydimethylsiloxane (PDMS) was reacted with 4,4′-diphenylmethane diisocyanate (MDI) and 1,4-butanediol (BDO) to form urea-carbamate functionalized PDMS (MDI-PDMS-BDO) with different hard segment contents. Furthermore, the modified graphene oxide (iGO) was obtained by the reaction between graphene oxide (GO) and MDI. iGO was further introduced into the functionalized PDMS to prepare iGO/urethane-urea functionalized PDMS composites (iGO/MDI-PDMS-BDO). An ordered structure was formed by the hard segments of the MDI-PDMS-BDO functionalized PDMS. A strong urea-based interface was also obtained between iGO and functionalized PDMS. iGO became the cross-linking center in the iGO/MDI-PDMS-BDO composites. Due to the ordered structure of hard segments and the iGO network formed in the PDMS composite with only 0.07 wt% iGO, the tensile strength and gas barrier properties of the iGO/MDI-PDMS-BDO composite were increased by 18 times and 64.27%, respectively, compared with pure PDMS.

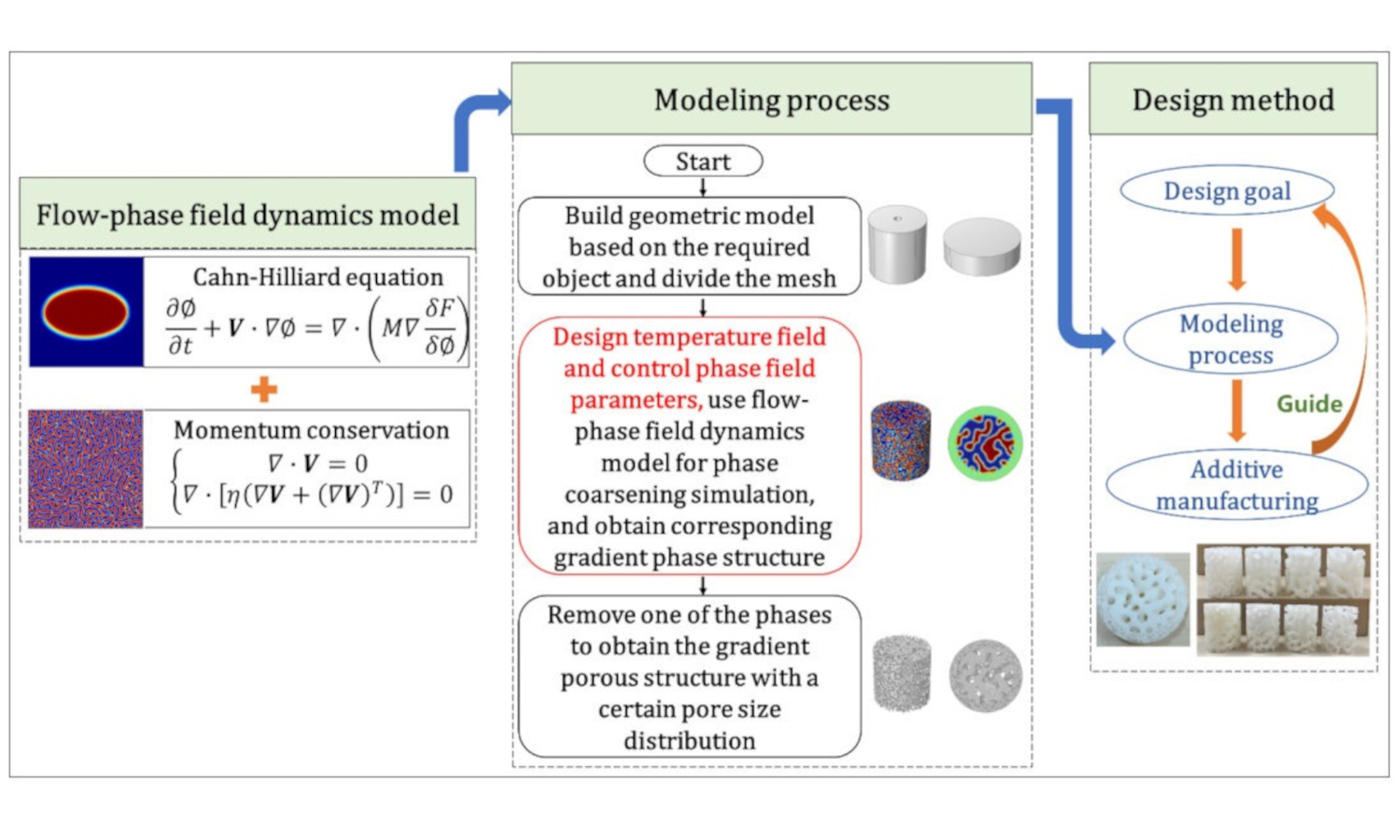

In this study, a novel methodology for the fabrication of gradient porous structures is introduced, predicated upon the phase evolution characteristics of immiscible polymer blends. Initially, a comprehensive flow-phase field dynamics model is developed. This model couples the principles of phase field theory and the dynamics of fluid flow to the two-phase evolution process, facilitating a numerical simulation of the phase evolution. Subsequently, the phase field parameters of model are determined and combined with the temperature field, thereby enabling a targeted and controlled fabrication of gradient porous structures. Finally, the efficacy and practical applicability of the proposed methodology are substantiated through the construction of illustrative examples. This approach, as delineated herein, provides a robust framework for the efficient design and realization of intricate, interconnected gradient porous structures with potential applications in various scientific and engineering domains.

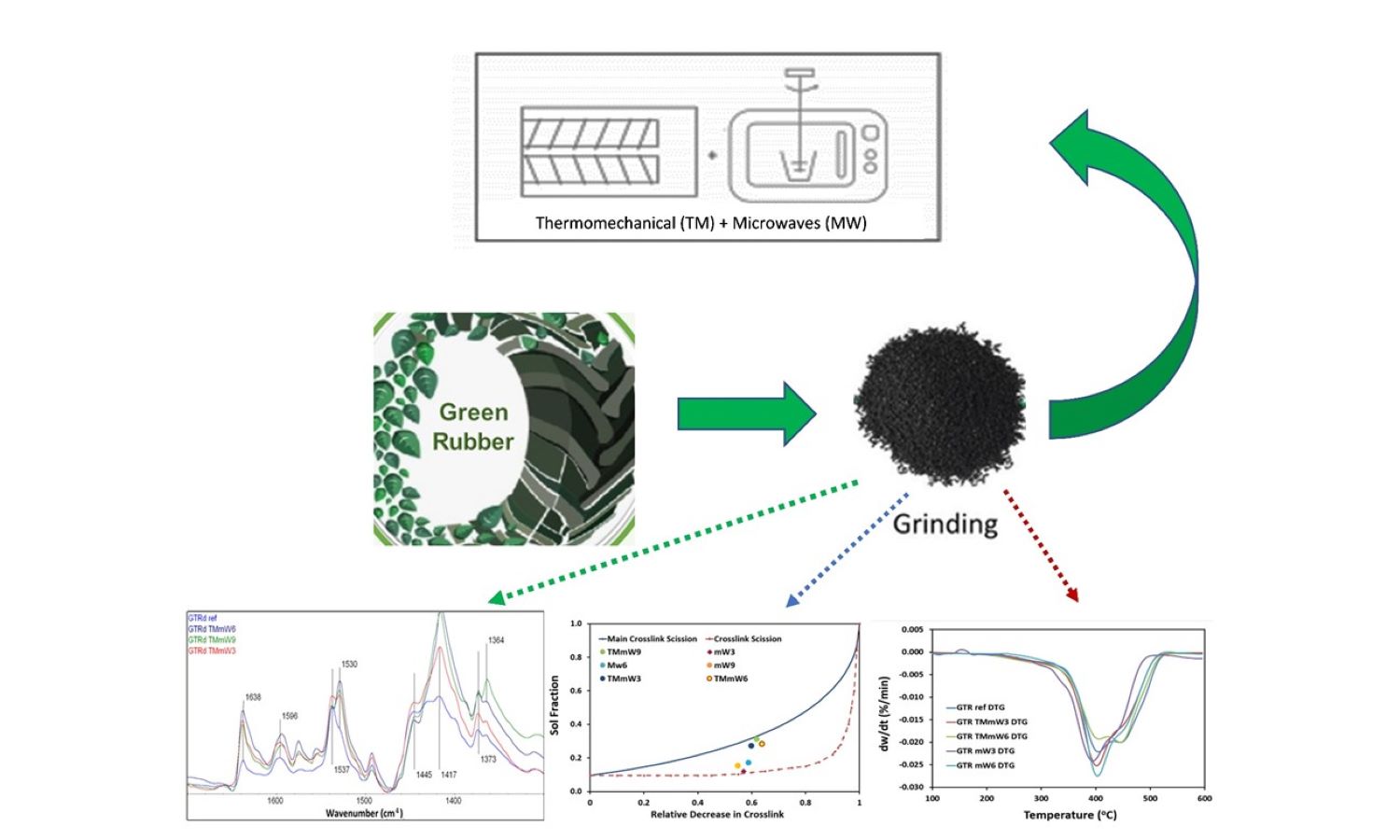

Microstructural phenomena in ground tire rubber (GTR) devulcanized via combined thermochemomechanical and microwave processes monitored by FTIR and DTGA assisted by other techniques

Xavier Colom, Mohammad Reza Saeb, Javier Cañavate

Vol. 18., No.9., Pages 950-961, 2024

DOI: 10.3144/expresspolymlett.2024.72

Vol. 18., No.9., Pages 950-961, 2024

DOI: 10.3144/expresspolymlett.2024.72

Analyzing rubber waste is crucial for value-added recycling, but the multitude of ingredients in vulcanized networks makes it challenging to characterize cross-linked rubbers. A combination of analytical techniques is usually required. In this study, two complementary characterization techniques, based on Fourier transform infrared (FTIR) spectroscopy and derivative thermogravimetric analysis (DTGA) were applied to analyze the structural, physical, and thermal behavior of ground tire rubber (GTR) samples devulcanized by two different processes. A set of samples was devulcanized by only microwaves (MW) while another set was treated with a combination of a thermochemomechanical (TM) process, which included the use of a devulcanization aid such as benzoyl peroxide, and microwaves. The combined technique proved to be more efficient in terms of the degree of devulcanization, significantly reducing the cross-linking density. However, the combined thermochemomechanical and microwave (TM/MW) devulcanization process resulted in greater degradation of the main rubber chains in the cross-linked network compared to the process using only microwaves.